What Distance Should Nails Be Spaced For Outside Wood Casings On A Window

Pro Moves for Fast and Authentic Casing

Ever been impressed by the skills of professionals? I beloved to watch professional person hockey, probably because three times a week I play the game in a local league. Although I have learned a thing or two watching the NHL, I will never come up close to matching their speed and accuracy on the ice.

When information technology comes to door and window casings, nevertheless, yous can learn skills to friction match professional cease carpenters, which will greatly improve your speed and accuracy. A house with 20 doors and xx windows will need 200 private pieces of casing to trim out the interior. That's 200 boards that will need to be measured, cut, fit, glued and nailed into position.

Professional end carpenters must find efficient ways to get this job washed. You may not accept plans to go pro as a trim carpenter, just you can benefit from pro tips in casing preparation, cutting multiples, consistent nailing sequence and precise adjustments.

Training

Getting the door jambs and window surrounds ready for casing varies a bit between remodel and new construction. Whether you are removing nails left over from the onetime casing or you lot are cutting off shims and beating back drywall on a new construction project, it's important to make certain that all of the windows and doors are ready before getting started.

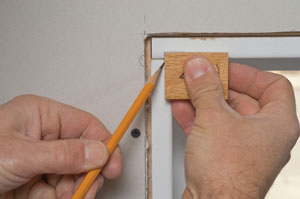

We pull all of the doors off the hinges and prepare them aside. This really helps in prepping the door jambs. Later cutting off any overhanging shims and beating back drywall (inside the premises of the planned casing), use a guess cake to mark the reveals on both the door jambs and window surrounds.

Make a list of the doors that need casing. Accept annotation of which doors are exterior doors. Because the stops are constructed differently, like-sized exterior doors volition accept slightly dissimilar casing lengths, so cutting these separately.

Make a list of the window environment sizes also. Oft yous will take a parts cut list from building the surrounds that can exist used as a reference for the windows. The important matter is to determine which windows have matching horizontal or vertical measurements.

Cutting Multiples

Perhaps the most important concept when casing more than than a couple of doors and windows is that casing lengths are usually repeated a number of times. Applying this concept, a pro can step upwardly to a miter saw table and in a few minutes cut all of the casing for an entire business firm.

The largest volume of matching casing sizes will exist found in the verticals of both windows and doors. For example, our house has 20 pieces of vertical window casing that are 62 inches in length. Information technology has 40 left-paw mitered and twoscore correct-hand mitered vertical door pieces that are 83-1/2 inches.

With numbers like these it'southward easy to see how setting a stop on the miter saw table and cutting all of these pieces at in one case would be toll effective. Still, smaller projects tin also do good from a production approach to cutting trim. My rule of thumb for using a stop on the saw is if y'all have iii or more pieces of the same length, then information technology's faster to utilize the stop than to mensurate and mark each private piece.

Not all of these pieces get cut to an verbal length. Room for adjustments must be built into your arrangement for installing window and door casings. At Oregon Carpenters nosotros cutting all of the header pieces (that is the peak horizontal pieces) for windows and doors to the exact length. All others become a little extra room for adjustments. After all, this is finish work, which means it'due south all about precision and quality. Nosotros'll see how this actress room plays out equally we continue.

To employ the multiple-slice concept, rough-cut enough stock slightly over-size to make all of the header pieces for your projection. Although this seems pretty basic, I've seen rookies incorrectly cut enough of material. Make sure yous cut the pieces long enough to suit the width of the casing. For example, 2-1/iv-inch casing requires a header slice that is 5 inches longer than the door size. A door that is 30 inches broad requires a horizontal casing piece that is a minimum of 35 inches. Withal, don't cutting it this shut when roughing out your material; 36 inches is a safer bet.

With all the header pieces rough-cut to length, cut a 45-caste miter on one end of all of the pieces. Take one piece to the nearest door and agree it into position so the short point of the miter aligns with the reveal mark. Mark the lesser edge of the casing slice at the other reveal mark and have the slice back to the saw.

Make sure you are cutting the 2nd miter in the opposite direction from the existing cutting, align the mark with the kerf cutting (or laser) on the proper side of the bract and cut the header to length. This is your blueprint header piece for all matching headers. Exam it for length at the matching doors or windows to brand certain information technology will work.

Utilise the pattern header to gear up the cease on the saw. Lock the saw head down, identify the slice against the blade and along the debate. Clamp, nail or tighten your stop against the sharp point at the other end of the slice. Cut the remaining matching header pieces by first making a 45-degree cutting on the same end equally your stop (e.g., on the left if the stop is on the left) and and then using this cut against the stop to cutting the others. Place each trim piece near the door or window where it volition be installed.

Head First

Nail upward all the header pieces, start with your 18-judge brad nailer using 1-1/4-inch brads. Marshal one cease with the reveal mark and so tack information technology in identify to the door jamb or window surround. Align the other stop and nail information technology up as well. Nail through the casing and into the jamb or surround every eight inches.

Back-nail all of the headers using your 18-gauge gun with ii-inch nails or a sixteen-guess nailer with ane-3/4 to 2-ane/2 inch nails. Dorsum-nails go through the casing almost the outside edge, through the drywall and into the framing. Back-nails should exist spaced at about 16 inches. This is an of import step. Having the header installed and back-nailed gives you a solid slice to suit for the remaining pieces of casing and prevents the miter from blowing autonomously, which can happen if the back-nails are added later.

In that location is no demand to mark the casing when cut to judge lengths. Hook the tape to one finish and motility the piece until the mark on the record is nearly aligned with the kerf marking on the saw table.Vertical Moves

With the headers installed, you can now mensurate for the trimmers (vertical pieces) while keeping in mind the multiple-slice cutting approach. Doors in areas where carpet will be installed can be cut so they are slightly above the subfloor. If the finished floor surface is in place, cut the verticals slightly long (1/four inch) to allow for miter adjustments. The trimmers can exist held abroad from the door jamb at the bottom equally you examination the miter. Only the upper 2 feet or so needs to exist aligned with the door jamb every bit yous check and adjust the miter. If the first 2 feet coming away from a miter looks good, you can pull the remainder in line every bit you smash information technology.

Window verticals should likewise be cut slightly long. In fact, you can save time by leaving the lesser cutting square until y'all take checked and adjusted the miter.

Cut all of the verticals and place them almost the door or window where each will be installed. Check each miter and arrange equally necessary before cut the verticals to length (if needed).

One of the all-time ways to brand accurate miter adjustments is to imitate the gap that y'all see at the door or window with the saw blade at the table. This is especially helpful when the long bespeak is touching and there is a gap at the short point. Take the slice dorsum to the saw, lock the head downward and rotate the saw's miter setting slightly then the gap you run into against the blade looks similar the one you saw confronting the header slice on your project. Lock in your miter adjustment on the saw.

Brand ii marks on the miter cutting at the cease where the gap is largest. When these marks disappear you have cut plenty to ensure that the miter has been changed across the entire length of the cut. Brand several passes with the saw if necessary and then y'all tin sneak up on your cut without cut off too much.

Go back to the door or window, cheque the miter again. If it'southward proficient, mark the piece to be cut for length. On windows this means transferring the reveal marking at the other end of the piece onto the casing. For doors you lot tin invert the slice, putting the long point on the floor and marking where the top edge of the header intersects the edge of the casing. Cut it foursquare at the mark.

You lot are now ready to glue and boom the vertical pieces in place. Run a bead of carpenters glue along the dorsum edge of the miter cut and assemble the joint in its concluding position. Clasp the miter together as you lot boom the first few inches into the jamb or window surround. If the casing piece is a chip warped so the lesser portion is going away from the door opening, back-nail the piece near the top before nailing the casing to the jamb.

Go along nailing the casing to the jamb or window environs except the lower i-1/two anxiety of the correct vertical slice on windows. Leave this section loose until the lower horizontal slice can be matched to it. Equally you boom the verticals, pay attention to the reveal on the jamb or surround to proceed it consistently 1/4 of an inch. You are now working out whatsoever warps or twists that are in your slice of casing and making it adjust to the directly lines of the door jamb or window surround.

At present, cut the lower horizontals for the picture-frame manner window casing. Cutting the pieces every bit multiples but add about ane/four inch to the length. Test the miter first on the left cease and brand adjustments. Test the miter at the correct end and adjust every bit needed, but get out the saw set up at the adjusted angle. If the miter looks good, transfer the correct reveal marker to the casing and cutting it to length using the adapted angle on the saw.

Gum the miters at both ends and boom the left half of the lower window horizontal piece into place. Pull the right miter together, shifting the horizontal piece upwardly or down and the vertical piece left or right until the miter looks skilful and end nailing both pieces.

Trim 45 Carpentry Assist

Milescraft's handy new Trim 45 is a marking and measuring tool to take the guesswork out of trim carpentry. The tool's unique adjustable reveal allows yous to ready a reveal of your choice from i/8 to one/2 inch in i/8-inch increments. Arrange the reveal just enough to embrace old paint lines with new trim, or set a bold reveal for heavy shadow lines. The Trim 45'due south tape-measure slots are positioned for easy and authentic measuring, and rare earth magnets hold the tape measure in identify. Mount the Trim 45 in a corner past using the built-in boom holes and measure long distances solitary. Plus, integrated pins permit y'all to measure out end trim length without fumbling with the tape measure on an awkward corner.

No Laser? Duct Tape It!

Install a slice of duct tape and cut information technology with the saw to go an authentic kerf marker. You can align the mark on your casing with the correct edge of the gap to speed up the process of making precise cuts.

Bridge over the kerf gap on the saw with a piece of duct tape.

Cut through the duct tape.

Align cut marks on the correct edge of the tape. Placing the mark on the other side would cut the piece brusk by the kerf of the saw bract.

This technique produces results authentic enough to split up the width of a pencil mark.

Gap at Long Point—Whorl It

A gap at the long point of a miter probably means the jamb or surround are slightly outside of the wall surface. This actually creates a compound angle. You lot can tip a chemical compound miter saw to create a piffling back-cutting plus suit the angle. What I usually practice, however, is leave the saw at 45 and roll the piece.

When a miter doesn't fit, discover where the gap is widest.

Mark the cease of the piece with "10"s to indicate where to take away fabric and slashes to make sure the new angle cuts all the style across the piece.

A gap at the long indicate can ordinarily be corrected by rolling the slice in the saw, which produces a compound angle.

Bump the slice to the saw bract for position. Enhance the saw clear before starting the motor.

After 1 pass you tin still come across the hash marks, which means you need to take a little more than material to become the cut to go all the way across the joint surface.

Gap at Brusk Betoken—Less Than 45

This miter has a gap on this side, which means it needs some textile taken off of the long point.

Mark an "X" at the long indicate where material needs to exist removed and slashes at the short point to indicate a complete cut.

Most saws have a lock-out to keep the set points from automatically jumping back to 45 degrees.

With experience you can friction match quarter degrees with what you saw as you tested the miter.

Another way to set the saw is to imitate the gap you saw when testing the miter. This is essentially a way of mentally scribing the piece to fit.

Source: https://extremehowto.com/trim-tips-for-doors-and-windows/

Posted by: malloyquitorger.blogspot.com

0 Response to "What Distance Should Nails Be Spaced For Outside Wood Casings On A Window"

Post a Comment